news

HAMMER PRESENTS ITS NEW STRUCTURE SYSTEM FOR VENTILATED FACADES

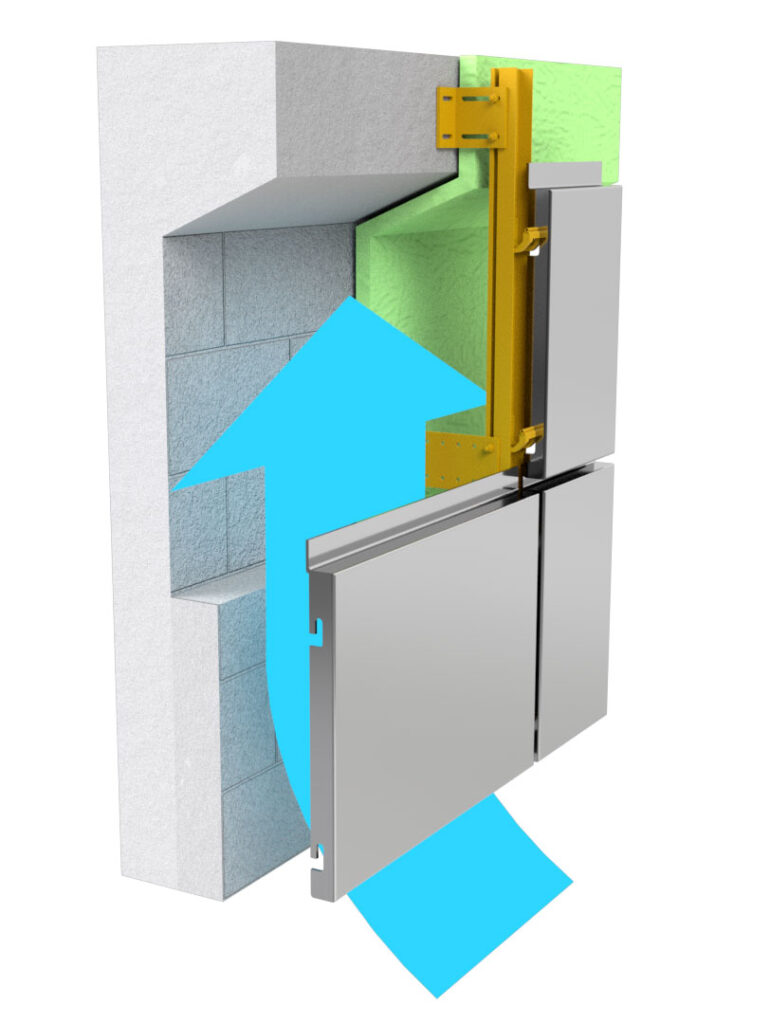

Hammer presents its new ventilated facade structure system.

Easy to use and versatile, it can be used to create ventilated facades with composite sandwich panels (ACM or WPC), stone materials, or to fix photovoltaic panels, creating photovoltaic systems on facades.

How it is configured

1) Primary vertical framing

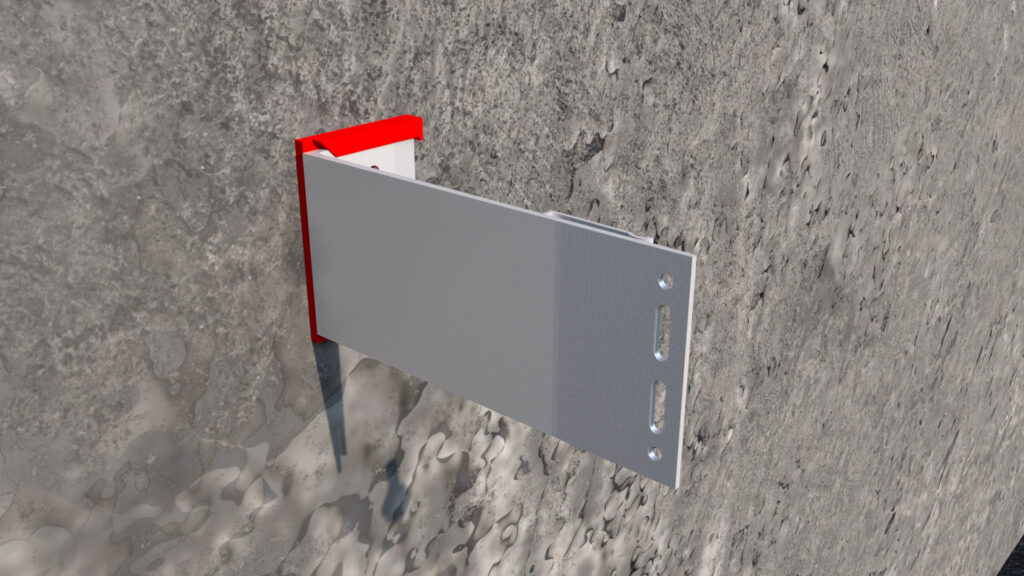

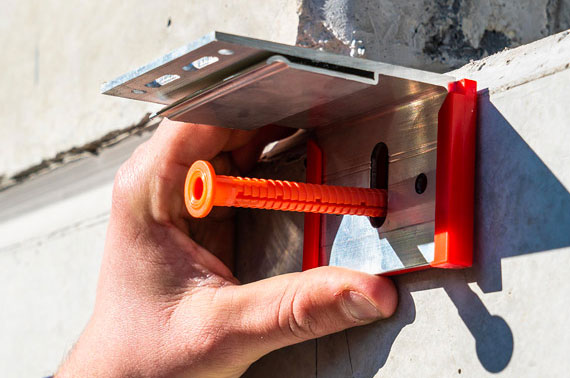

Brackets of various lengths, available in aluminum in the “Basic” series (codes HF-LBA) and “Strong” series (codes HF-LSA) or in stainless steel with the “Premium” series (codes HF-LPI), are fixed to the external wall of the building to space the chosen cladding from the wall, thus creating ventilation for the facade.

They are fixed using appropriately sized mechanical or chemical anchors (not supplied by Hammer).

The use of the Thermalstop element (codes HF-TS), always supplied in combination with all bracket series, is essential as it significantly reduces the thermal bridge between the outside and inside of the building on which the ventilated facade is installed.

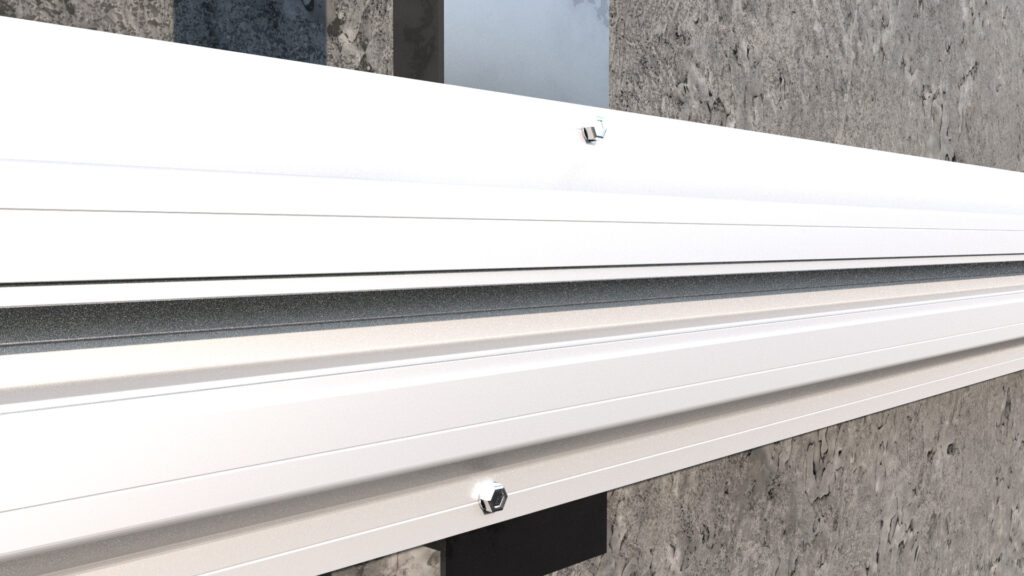

The upright profiles (codes HF-PR) are inserted into the brackets from the front thanks to the internal pockets, which have a curvature that improves anchoring before fixing.

The upright profiles are made of extruded 6060 aluminum alloy, available in different T or L sections depending on the project, and are easily fixed using HF-VI stainless steel self-tapping screws.

All Hammer brackets have both holes and slots to allow maximum freedom during bar installation, which must follow the “fixed point” and “flexible point” fixing pattern; this pattern allows longitudinal movement and compensates for thermal expansion.

Here is an example:

For cladding with riveted or screwed ACM panels, T-shaped upright profiles are used, code HE-PRT-01 (with a length of 6500 mm) or code HE-PRT-02 (with a length of 6000 mm), or the L-shaped profile code HE-PRL-01 with a length of 6500 mm.

For ACM box panels, use the HE-PRY-01 upright profile to which the pre-assembled aluminum hooks, code 1053, are attached for installing the “boxes”.

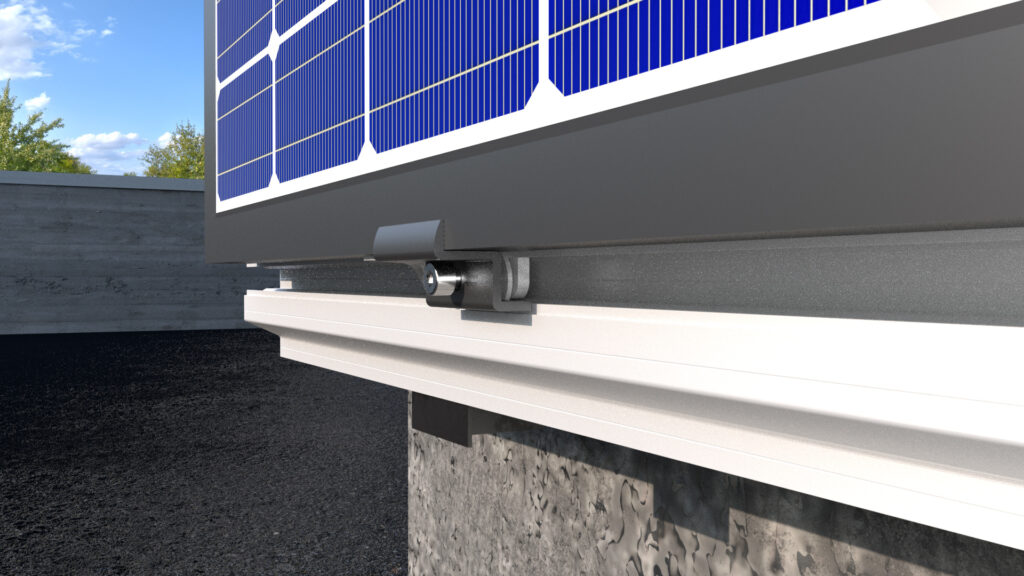

2) Secondary horizontal framing

The secondary framing is created with crossbars fixed to the vertical uprights using self-drilling screws (codes HF-VI). For the construction of photovoltaic facades, Hammer has designed the HE-PR-401 extruded aluminum profile in 6060 alloy.

3) Fasteners

Depending on the type of panel chosen for the exterior of the facade, a different type of fastener must be used.

How to fix composite or ACM panels

For riveted or screwed panels, self-drilling screws must be used for fixing to T-shaped profiles, codes HE-PRT-01, HE-PRT-02 or HE-PRL-01.

For ACM box panels, use pre-assembled aluminum hooks code 1053. The hooks are supplied pre-assembled with screws and cams and they have to be inserted frontally into the HE-PRY-01 upright profile; then the “boxes” have to be hooked onto them. The 8 mm EPDM spacer code 1052 keeps the boxes in position by absorbing micro-expansions.

How to fix stone panels

Stone cladding is fixed using two different types of stainless steel clips.

HF-CLN clips can be used to create cladding with concealed fixings, while HF-CLV clips can be used to install facade cladding with visible fixings, depending on the architect’s preference.

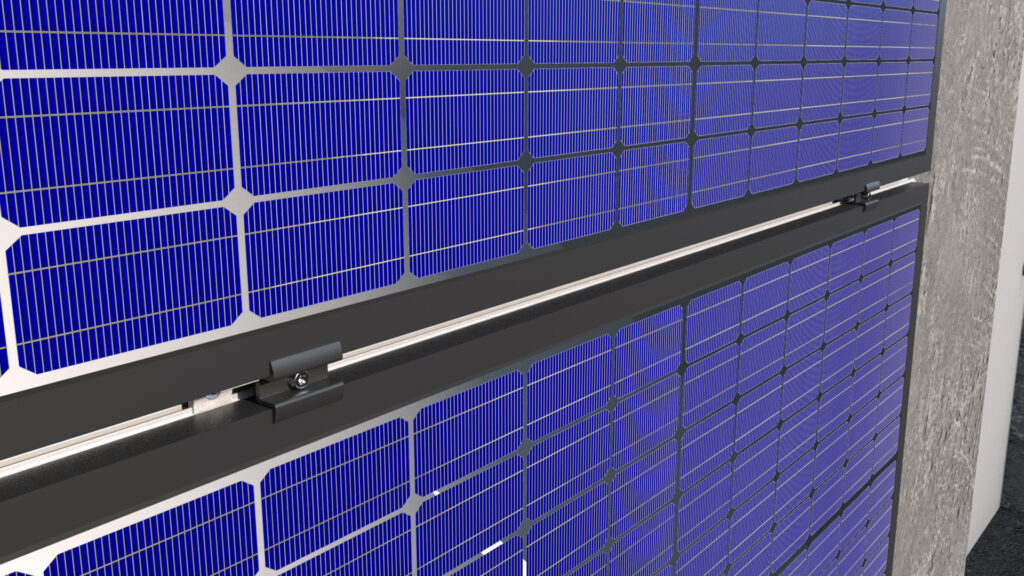

How to fix photovoltaic panels to the façade

To create photovoltaic installation on the façade to create ventilated photovoltaic façades capable of producing green electricity, aluminum bracket elements are inserted into the HE-PR-401 profiles of the second horizontal frame. They are fixed in place using stainless steel screws.

Two brackets support one panel and, in the event of maintenance, allow only the single panel to be removed and not the entire column of panels, simplifying both installation and any future maintenance.

Finally, the photovoltaic panels are fixed in place using RLS (Rapid Locking System) intermediate and terminal clamps, which can be supplied with a black oxidation surface finish to improve the aesthetics of the facade.

For further information, please contact us at +39 (0)141-951449 or e-mail us at hammer@hammer.biz.